The common label for metal laser cutting machines is flexibility, so what is flexibility?

First of all, from the literal point of view, flexibility means that it is more flexible in the production process. Flexible production means that different production tasks can be completed in production, and market demand can be quickly adjusted to maximize resource utilization.

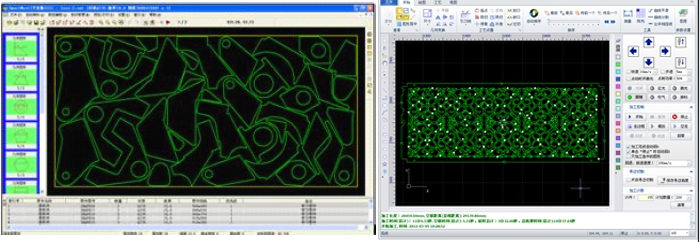

Laser cutting machine is an important equipment for flexible production. The flexibility of fiber laser cutting machine refers to the change of processing combination: The laser beam adopts two methods: direct and guiding. The laser can be rotated, tilted, up, down, left and right, etc. It can process the vertical surface of the workpiece and other complex workpiece surfaces; and the direct drive has no free motion and high precision. Using a machine to move or multi-axis to flip parts under the beam, it is possible to machine parts that are difficult to machine using conventional methods. The laser head can move freely up, down, left and right, the workpiece can be fixed during machining, and the machining of complex workpieces can still be realized. As long as the rotary rotary table is used, parts with larger axial stroke can be processed. The laser beam is controlled by auto focus. The linear axis of the laser system can be positioned along the optical axis or any axis to keep the beam focused; the focus position is accurate at any time and the travel is unlimited.

Therefore, the metal laser cutting machine can realize one-time processing and forming of the sheet metal parts. No matter how complicated the sheet metal parts are, as long as the drawing can be drawn in the computer, the processing can be realized.