Pain Points Of Leather Cutting Industry

1. There are many defects in the leather, and the efficiency of manual identification is low.

2. Manual drawing, cutting efficiency is too low and inaccurate

3. The typesetting is diversified, and the order requirements are getting higher and higher.

4. There are many kinds of leather and cut pieces, and the management is difficult.

5. Manual nesting, low utilization rate of raw materials.

6. High technical requirements for workers and high wages.

7. The leather cutting, punching, marking and other processes are complicated.

Why Choose Bangzheng Leather Multi-Layer Fabric Cutting Machine

Performance of leather cutting machine

1. The platform detection device automatically adjusts the knife pressure, the platform is flat and the cutting is perfect.

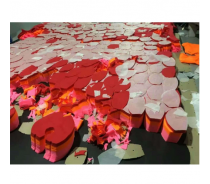

2. High-precision digital leather cutting machine, which can be cited separately and easily cut into small pieces.

3. Anti-collision and built-in automatic sensing device ensure the safety of the automatic leather cutting machine.

4. High efficiency can be achieved without making high-cost cutting dies.

5. Automatic cnc leather cutting machine can save cost while maintaining speed and precision.

|

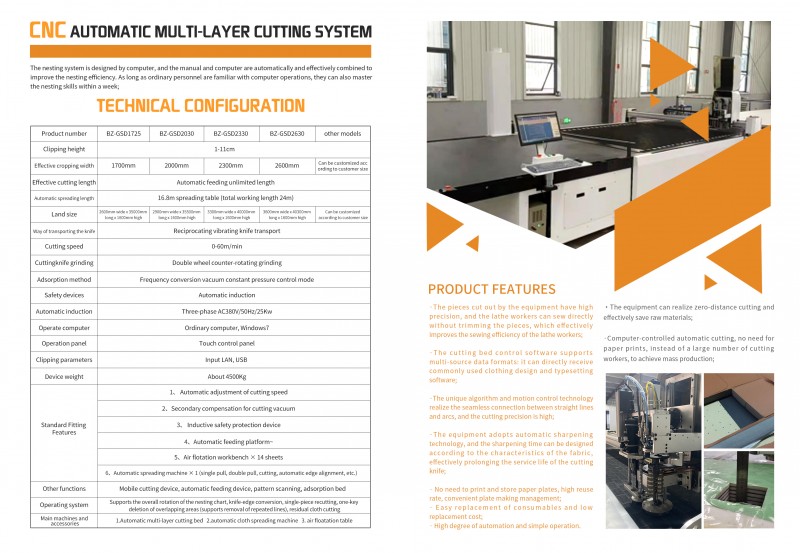

Product number |

BZ-1725D |

|

Clipping height |

1-11cm |

|

Effective cropping width |

1700mm |

|

Effective cutting length |

Automatic feeding unlimited length |

|

Automatic spreading length |

16.8m spreading table (total working length 24m) |

|

Land size |

2600mm wide x 65000mm long x 1600mm high |

|

Way of transporting the knife |

Reciprocating vibrating knife transport |

|

Cutting speed |

0-60m/min |

|

Cuttingknife grinding |

Double wheel counter-rotating grinding |

|

Adsorption method |

Frequency conversion vacuum constant pressure control mode |

|

Safety devices |

automatic induction |

|

Automatic induction |

Three-phase AC380V/50Hz/25Kw |

|

Operate computer |

Ordinary computer, Windows7 |

|

Operation panel |

touch control panel |

|

Clipping parameters |

Input LAN, USB |

|

Device weight |

about 4500Kg |

|

Standard Fitting Features |

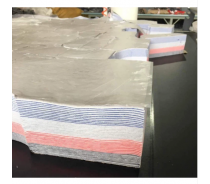

Automatic adjustment of cutting speed Secondary compensation for cutting vacuum Inductive safety protection device Automatic feeding platform~ Air flotation workbench × 14 sheets Automatic spreading machine × 1 (single pull, double pull, cutting, automatic edge alignment, etc.) |

|

Other functions |

Mobile cutting device, automatic feeding device, pattern scanning, adsorption bed |

|

Operating system |

Supports the overall rotation of the nesting chart, knife-edge conversion, single-piece recutting, one-key deletion of overlapping areas (supports removal of repeated lines), residual cloth cutting |

|

Automatic multi-layer cutting bed, automatic cloth spreading machine, air floatation table |