Bangzheng automatic multi-layer cloth cutting machine can input marking and cutting data through USB or through CAD system network to increase flexibility. Bangzheng can not only provide precise, efficient and durable industrial fabric cutting machines, but also provide just the right cutting technology for your specific application.

Bangzheng CNC provides a wide range of software application options, all software applications are optimized to provide the most advanced and simplified digital control of the cutting process, with the best output performance, peripheral software covers solutions from pattern design and optimization to the entire cutting process to the end Cutting products. Bangzheng cutting software is specially designed to meet the needs of fabric cutting customers in the clothing and home textile industries.

Automatic multi-layer cloth cutting machine is usually suitable for materials:

Cotton is generally used in casual wear, underwear and fashion.

Burlap is commonly used to make casual and work wear. Its advantages are moisture absorption and heat conduction, strong air permeability, and its disadvantages are uncomfortable wearing and rough appearance.

Silk is most commonly used to make women's clothing.

Woolen is often used in formal high-end clothing, such as dress suits. Its advantages are elegant and flexible, but its disadvantage is that it is difficult to wash.

Leather is generally used to make winter clothes. Its advantage is that it is light and warm, but its disadvantage is that it is expensive and requires a high degree of care.

Chemical fibers are textiles made of fibers made of polymer compounds.

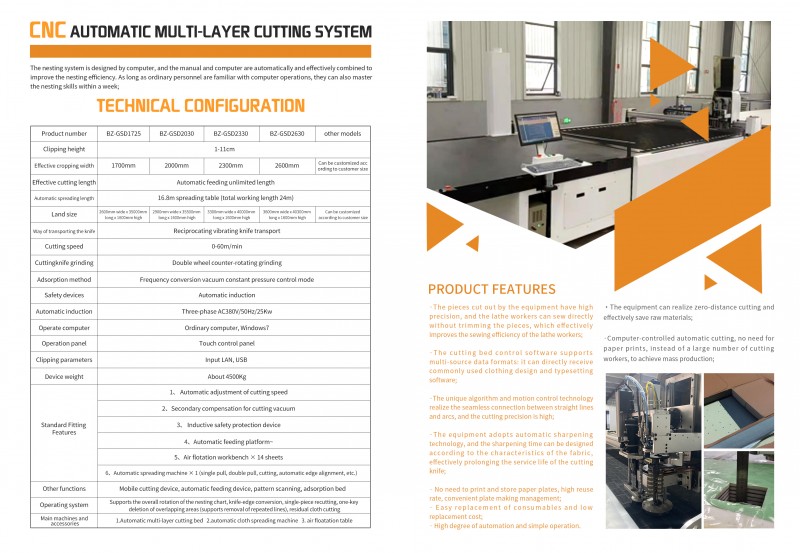

Product number

BZ-1725D

clipping height

1-11cm

Effective cropping width

1700mm

Effective cutting length

Automatic feeding unlimited length

Automatic spreading length

16.8m spreading table (total working length 24m)

Land size

2600mm wide x 65000mm long x 1600mm high

Way of transporting the knife

Reciprocating vibrating knife transport

cutting speed

0-60m/min

Cuttingknife grinding

Double wheel counter-rotating grinding

Adsorption method

Frequency conversion vacuum constant pressure control mode

safety devices

automatic induction

automatic induction

Three-phase AC380V/50Hz/25Kw

operate computer

Ordinary computer, Windows7

operation panel

touch control panel

clipping parameters

Input LAN, USB

Device weight

about 4500Kg

Standard Fitting Features

1、 Automatic adjustment of cutting speed

2、Secondary compensation for cutting vacuum

3、 Inductive safety protection device

4、Automatic feeding platform~

5、Air flotation workbench × 14 sheets

6、Automatic spreading machine × 1 (single pull, double pull, cutting, automatic edge alignment, etc.)

Other functions

Mobile cutting device, automatic feeding device, pattern scanning, adsorption bed

operating system

Supports the overall rotation of the nesting chart, knife-edge conversion, single-piece recutting, one-key deletion of overlapping areas (supports removal of repeated lines), residual cloth cutting

Automatic multi-layer cutting bed, automatic cloth spreading machine, air floatation table