Product Application

1.QT10-15 Brick Production Line is fully automatic brick making machine, which can make different sizes of hollow blocks, solid bricks, paver and curbstone by changing moulds.

2. QT10-15 Brick Making Machine adopt to hydraulic pressure moulding system , so the brick machine has more stable and higher-efficiency working status and the bricks produced are of better quality, larger density and higher strength.

|

MAIN SPECIFICATIONS

|

|||

|

Dimension of host machine

|

35002300x2930mm

|

Power of host machine

|

37kw

|

|

Weight of host machine

|

9.8T

|

Vibration force

|

100KN

|

|

Molding area

|

1196x880mm

|

Mixer Model

|

JS750

|

|

Water consumption

|

10-20T/Day

|

Pallet size

|

1300900x30mm

|

|

Workshop

|

260M2

|

|

|

Main Features

1) The motor for the host machine is Germany SIEMENS brand or ABB brand

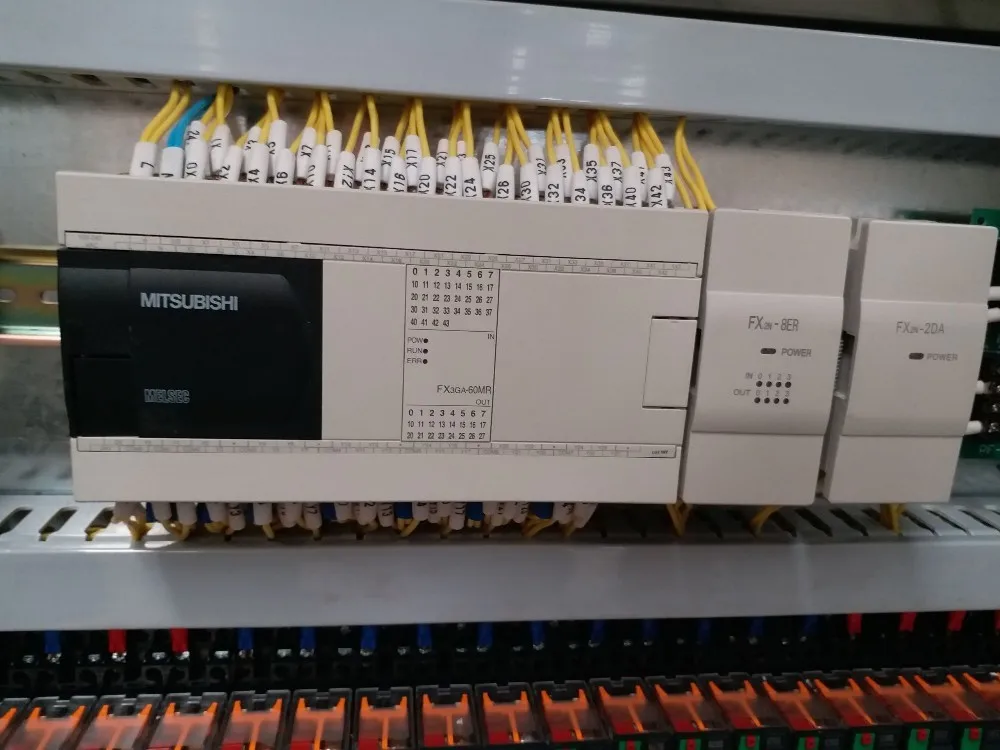

2) Control PLC: we select original Japan Mitsubishi PLCcombine with independently develop machine control program, assure stable and high efficiency working status

3) The switch will use France Schneider brand and Japan Omron

4) Mould: newest heat treatment device and carburizing treatment will assure longer mould life span and ensure the strength of mould reach to 54-58 HRC so that the mould can be used more than 100 thousand times.

5)Material and welding: all materials and spare parts selected according to international CE standard, Carbon dioxide protection welding will assure whole line stable running.

Machine Parts

Name: JS750 Mixer

Dimension: 4195x23002800mm

Charging capacity: 1200L

Discharding capacity: 750L

Total weight: 6800kg

Main Features

Name: Motor

Brand: ABB or SIEMENS

Original: Germany

Germany famous motor, high quality, international warranty service, stable voltage, high efficiency, long lifetime.

Machine Parts

Mitsubishi PLC Control Unit

Machine adopts Mitsubishi brand PLC , can make the machine Automatic Running.

WIth touch Screen can set Machine parameter easily

Main Features

Human Design Hydraulic station

Hydraulic station with high cacoity and adopts Japan Yuken brand Hydraulic valve and pump .

with water cooling system ,can cool the oil temperature with flowing water ,keep working for a long time .