矿用激光熔覆机

激光加工是上世纪末开发的先进制造技术。它用于各种领域,如机械制造,我高架车,运输车辆,模具,石油化工,勘探,电力,纺织,航空航天等领域。激光表面处理产品的主要特点是:硬度高,效率高,质量好,可以达到高耐磨性,高强度,高耐腐蚀性,高红硬度等无法达到的性能。传统技术,并不能实现合作传统方法。实现热处理或修复方法。

激光加工技术主要包括:激光表面相变硬化(淬火)加工,激光熔覆(修复)加工,激光表面合金化,激光熔化等。

激光淬火的优点

加热和冷却速度快,淬火效果好;

激光通过加热硬化nduction from the surface and inside, no cooling medium, no pollution to the environment.

Self-tempering process, no need to temper, process is simple;

only heating the surface, the overall performance of the workpiece is not affected;

Heating parts can be precisely controlled and easy to automate production;

Specially designed light guide system can be used for quenching deep holes, inner holes, grooves, blind holes, etc.

In the industrial field, traditional processes such as induction hardening and chemical heat treatment are gradually being replaced.

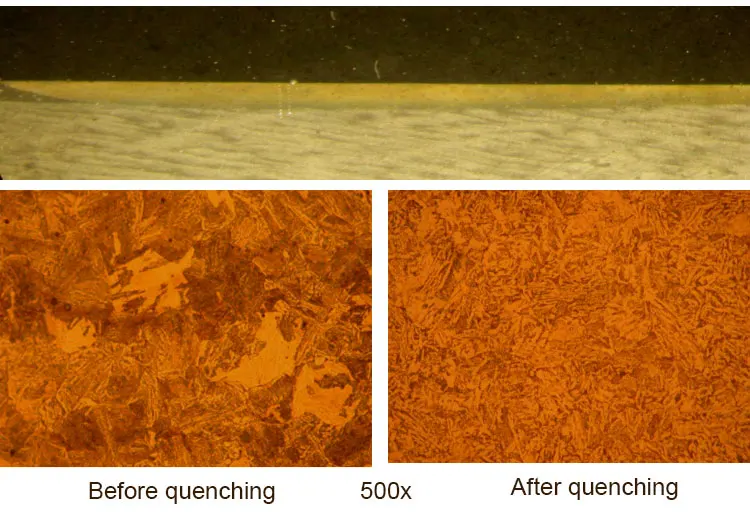

Anatomical Analysis of the Tooth Surface before and after Laser Quenching of Internal Ring Gear

Specification

The product is composed with TFL-6K/10K laser source, specific 60000 calories water chiller, CNC processing machine tool, auto powder delivery machine, optical path system and CNC control system.

| Model | GS-TFL-6K/10K | ||

| Laser source | TFL-6K/10K laser source/ semi-Laser source conductor laser source | ||

| Optical system | Fly optical path, Light path diameterφ70 | ||

| Manual type swing bald,Turning Angle±60°manual adjustment | |||

| CNC machine tools | |||

| model | 2 M | 2.5 M | 3.5 M |

| Working area (mm) | 2000*600*500 | 2500*1000*5000 | 3500*1000*500 |

| X, Y, Z axle working speed | 0 - 5000 m/min | ||

| Location accuracy | ±0.1 mm / 300 mm | ||

| Relocation accuracy | ±0.05 mm | ||

| Horizontal rotating table | |||

| Max. chuck diameter |

Three claw Φ500/center |

Four claw Φ630/center |

Four claw Φ630/center |

| Rotating speed | 0.5 - 15 rpm | 0.05 - 5 rpm | 0.05 - 5 rpm |

| 平台尺寸(mm) | 3860 * 1450 * 280 | 5560 * 1000 * 280 | 7000 * 1200 * 350 |

| 中心轴 |

轴承直径 |

轴承直径 |

轴承直径 |

| 最大。工件长度 | 2500毫米 | 3500毫米 | 4000毫米 |

| 最大。工件直径 | Φ800 | Φ1350 | Φ1500 |

| 最大。工件重量 | 5 T | 10吨 | 15 T. |

| 有限公司控制系统 | 西门子西门子828D交流伺服电机 | ||

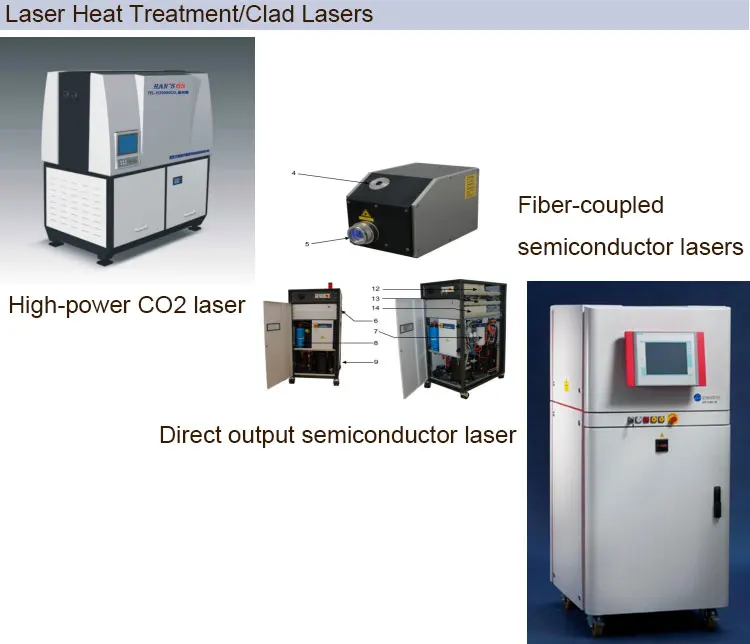

激光热处理/包层激光器