完整的设备功能

1.可选择包层,材料公司nsumption很低。

2.由于快速加热和冷却,激光熔覆层的微观结构均匀致密,微观缺陷少,性能优于其他工艺。

这是一个非合作的ntact类型的过程易于自动化并实现灵活的处理。

4.可以精确控制激光束的功率,位置和形状,可以很容易地实现选择区域甚至微区域包层,并且对基板的热效应最小。

5.包层的稀释度小,可以精确控制。

有限公司激光融合覆盖与传统之间的对比最终程序:

| 激光熔合覆盖后的不锈钢腿 | Traditio最小的腿 |

| 没有涂层程序 | 涂层,环境nings huring |

| 部分磨损,部分恢复 | 部分磨损,整体恢复 |

| 融合覆盖层与基体结合 | 涂层用基质捆扎 |

| 5年内无需维护 | 每1至2年一次维护 |

| 使用后修复再生 | 2-3次维护后丢失 |

规范:

| 名称 | 牌 |

| CNC control system and drive motor | SIEMENS |

| Ball screw, guide rail, slider |

ACEPILLAR-TAIWAN |

| Reducer | Taiwan |

| Window lens | Ⅱ-VI (USA) |

| Dynamometer | BMEI |

| vacuum pump | Beijing |

| power module | Shandong |

| refrigeration compressor | Tianjin |

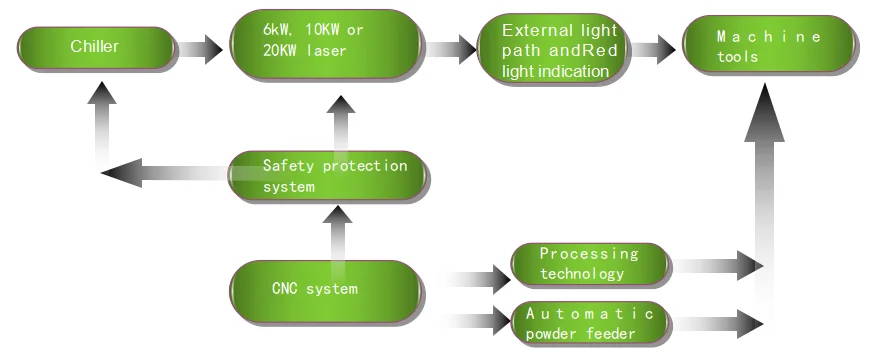

Control system and heat treatment software

Siemens 808D ac servo system is used in the numerical control system, set a work station of integrated control, centralized control of laser machining bed, laser source, powder feeder and light route system and so on; Control work station at the same time to separate controlling each part, with functions of automatic and manual switch;

Control system has strong functions: fulfilling many kinds of data “analog to digital-digital to analog” conversion, laser machining track display, digital information processing, fault analysis and alarm, wrong operation chain protection function;

Can do all kinds of procedure editing of machining heat treatment, laser cladding and implement automatic control for the whole process program;

Numerical control each shaft with integral interpolation function, numerical control system has the function of workpiece zoom, image features, the rotation function, linear/circular arc/slash interpolation function and the automatic connection;

Basic equipment composition

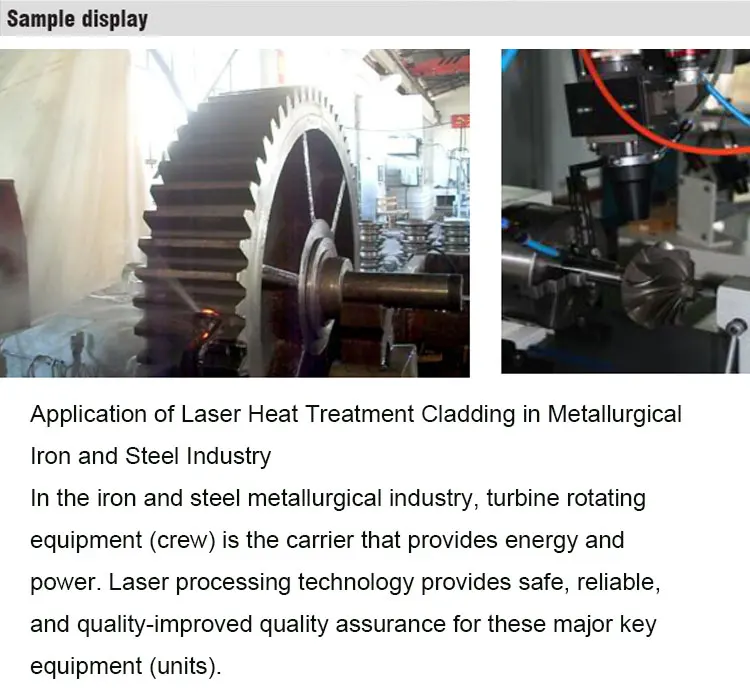

Application of Laser Heat Treatment Cladding in metallurgical Iron and Steel Industry

In the iron and steel metallurgical industry, turbine rotating equipment (crew) is the carrier that provides energy and power. Laser processing technology provides safe, reliable, and quality-improved quality assurance for these major key equipment (units).

For example, the moving and statio钢铁公司的轴流式压缩机的叶片,以及移动和站立高炉涡轮“两拖”式TRT装置的叶片已投入生产,运行平稳可靠。此外,所有移动和站立通过激光熔覆成型技术修复的两个单元的刀片与原始设计和制造的新刀片相比,可将使用寿命延长50-100%。Ø这两个设备可以节省公司的费用还有500多个。百万元维修资金。