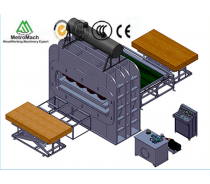

PRODUCT DEscriptION

Double sides Short Cycle laminating hot press is mainly used to produce two sides decorated board. suitable for laminating melamine paper,wearable paper and balance paper in both sides of HDF board to produce laminate flooring.

1. Aging treatment: The steel used in our lamination machine was after aging treatment, that's make our material more uniform stress.

2. frame mechanism: The closed frame is strengthened, which will ensure its working accuracy by appropriate design, reinforced mechanical properties and machining each surface.

3. Oil cylinder adopts the advanced sealing technology, cast-steel cylinder body, chill-iron plunger and good machining accuracy, all of which will extend the working life of cylinder.

4. Adopt PLC control and touch screen. easily set the time and pressure.

| Total pressure | Main cylinder Diameter | Number of cylinders | panel size |

| 1200Ton | φ320mm | 6pcs |

4x8ft/9ft, 5x8ft, 6x8ft, 6x9ft, 7x9ft etc |

| 1400Ton | φ340mm | 6pcs | |

| 1600Ton | φ320mm | 8pcs | |

| 1800Ton | φ340mm | 8pcs |

TECHNICAL PAREMETERS

| Model | TLY114×8/14-II |

| Nominal gross pressure | 14000Kn |

| Direction of feeding plate | HORIZONTAL |

| Layer Counting | 1 Layer |

| Distance between hot platens | 200mm |

| Numbers of hot platens | 2 pcs |

| Dimension of Hot Platens |

2600×1400×140mm(up) 2600×1400×100mm(down) |

| Numbers of Cylinder | 6 Pcs |

| Diameter of Cylinder | Φ340mm |

| Stroke of Cylinder | 200mm |

| Pressurization | ≤25Mpa |

| The Position of Cylinder | up |

| Empty Closing Time | about 2-3 s |

| Max Temperature | <210 |

| Numbers of Lift Cylinder | 4pcs |

| Diameter of Cylinder | Φ80mm, Φ30 |

| Stroke of Cylinder | 200mm |

| High Pressure Pump Flowing | about 89L/min |

| Allowed Pressure | ≤25Mpa |

| Power | 37Kw |

| Pressure of Unit Plate Blank | 47Kgf/cm2 |

| Control Method | Automatic pump station |

| frame steel plate thickness | 60mm |

| Total weight | 37000kgs |

PRODUCT SHOW

MORE about US

Welcome to Contact

Whatsapp: +8615054649650

Wechat: +8615254920677

Email: maylv@metromach.com