Main Parameter

|

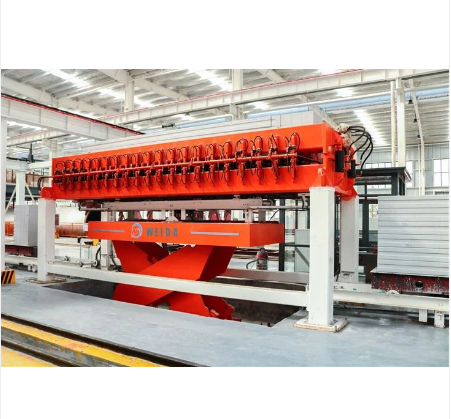

Equipment use |

1. It is mainly used for the splitting of finished products, separating the finished products which are glued together after steaming and nourishing. 2. The equipment is composed of the main frame, upper and lower breaking plate frame, separation device, clamping device, scissors and fork lifting device, hydraulic station and other parts. |

|

Technical specification(1) |

Hydraulic station power: 24kw, servo motor. |

|

Technical specification(2) |

1. The clamping and splitting of the equipment are driven by hydraulic pressure; 2. Servo motor hydraulic station is adopted to separate the plate breaking machine, which is energy saving and environmental protection, and the flow pressure can be Good control. 3. The lifting of the billet adopts the scissors and fork structure, and the lifting bit is controlled by the cable encoder To ensure the precision of the relative position of the cutting seam and the breaking frame of the plate. Knife and fork Type lifting platform, equipped with maintenance pole, to ensure the safety of maintenance; 4. For different specifications of the plate, the chuck position can be adjusted. Minimum upper and lower chuck spacing: 50mm; Maximum clamping stroke :75mm (single side); Upper and lower chuck: secondary pressure type clamping mode; Chuck clamping pressure: 0-15mpa; Breaking minimum thickness: 50mm. |

Hot Tags: lift the trigger, China lift the trigger suppliers, factory, Lift The Trigger, Parallel Stacking Chain System For Aac Plant, AAC Block Handing Crane, AAC Block Packing Section, Rotating Clamp Crane For Aac Plant