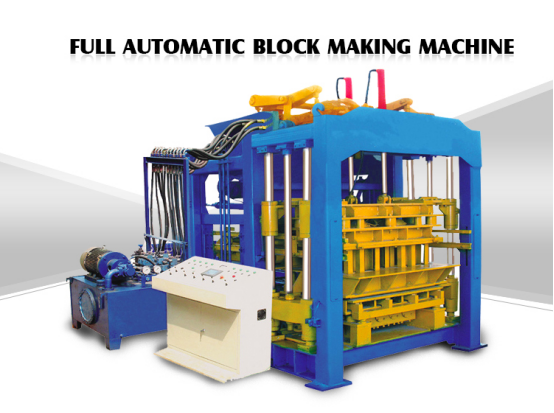

QT8-15 Automatic concrete brick making machine

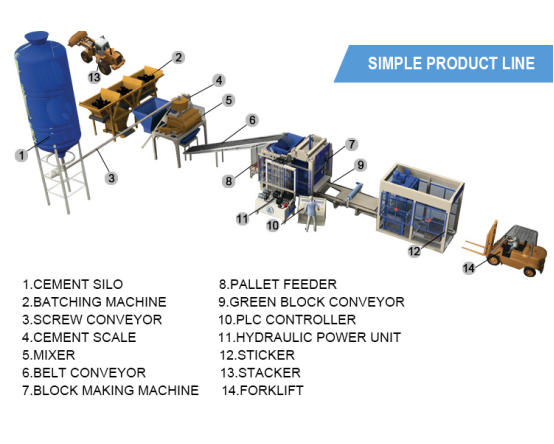

1).This machine line produce all kinds of hollow, solid, paving, interlock bricks/blocks andcurbstones.

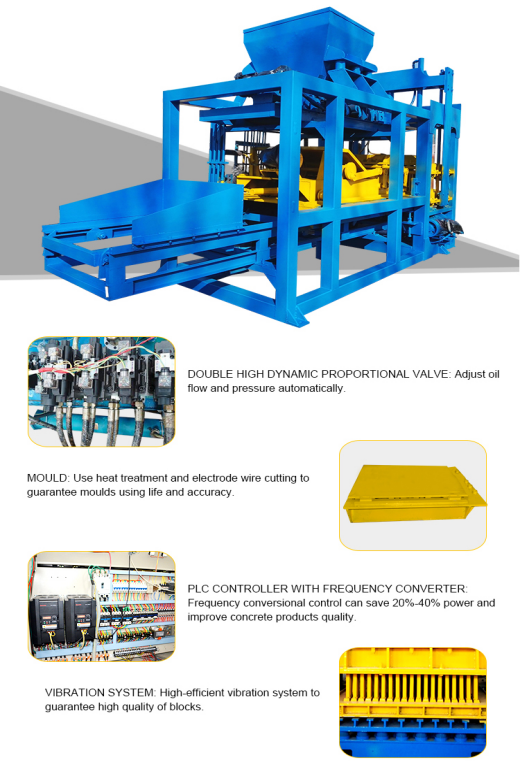

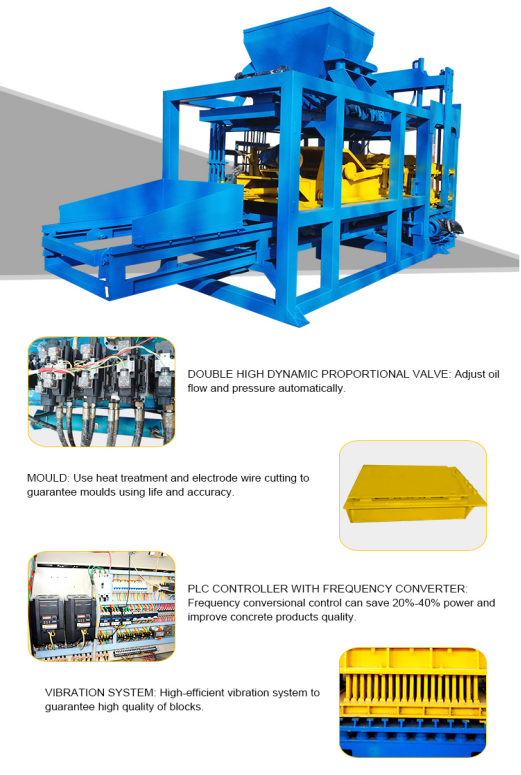

2).Machine use PLC automatic control system and hydraulic pressure system.

4 working sections are batching raw material, mixing, block/brick forming, and stacking.

3).Machine quality is guaranteed. Like high quality national standard steel, siemens or ABB motors, Schneider or CHNT electric units, and Mistubishi PLC control system. Line cutting technology ensure accurate size. Carburizing technology increase mould service life. CE, SGS, ISO9001 certificated.

The main parameters of QT8-15

TECHNICAL PARAMETERS

|

Technical Parameters of QT8-15 block machine |

|

|

Overall Dimension |

8300*1860*3000mm |

|

Rated Pressure |

21MPa |

|

Main Vibration Form |

Platform Vibration |

|

Vibration Frequency |

2800~4500 ( r/min) |

|

Pallet Size |

950*900mm |

|

Molding cycle |

15-25 (s) |

|

Overall Power |

55.5KW |

|

Vibration Force |

60KN |

|

Total Mass |

12.5T |

|

Demolding method |

Hydraulic |

|

General water consumption |

12T/Day |

|

Factory Area |

600m2 |

|

Applied Products |

Concrete blocks, hollow/solid blocks, pavers, interlocking blocks , curbstone, colored pavers ,etc. |

|

Raw Material |

Crushed stone, sand , cement, dust, and fly ash, gravel, slag, and other raw material , etc. |

|

Size(LxWxH) |

Pcs/Mould |

Pcs/ Hr |

Pcs/8hours |

|

400200200 |

8 |

1920 |

15360 |

|

400100200 |

15 |

3600 |

28800 |

|

20010060 |

32 |

7680 |

611440 |

|

240115x53 |

42 |

10080 |

80640 |

FAQ:

1.What is the Raw Material of Block Making Machine of our company?

Our Equipment is Concrete Block Making Machine.The Raw Materials of Concrete are Water, Cement, Sand, Stone Powder, Fly Ash, Slag etc..

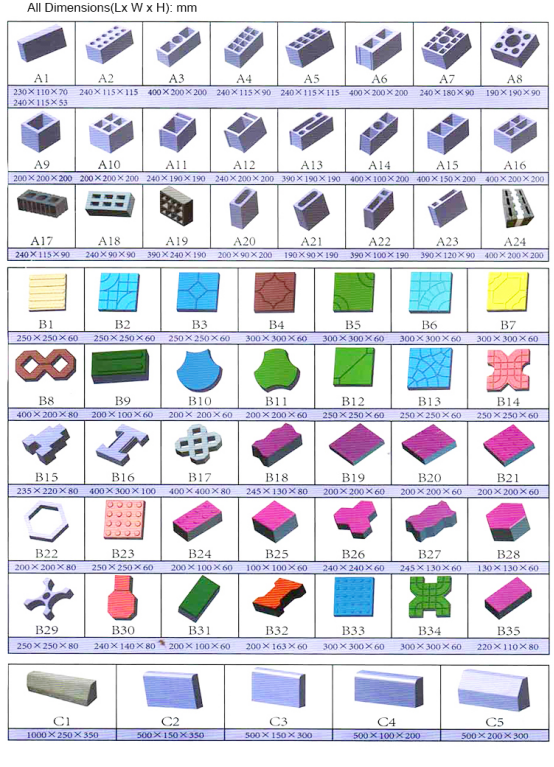

2.Can we produce various sizes and shapes of Blocks?

Our machine can produce various sizes and shapes of Blocks by changing different Mould.Some of Moulds are available in our company.The Moulds also can be customized by customer’s block sizes and shapes.Or we can design the relative Mould based on your block size,picture or drawing.Normally one Mould can produce one kind of Blocks.

3.What should we do if machine do not work any more?

We will send technicians for guiding Installation, Commissioning,Trial Production while training the technicians of customer after the equipments arrived at the site;Normally our equipments do not have big problem.The Technicians of customer can take care of it with our help if any problem occur.We usually recommend customers to purchase part of Spare Parts as backup,if has big problem,we will send out engineer there to help you. Our company has more than Thirty years experiences for producing Block Making Machine with stable and reliable Equipment Quality.

4.What is the strength of Blocks made by our company.

Our Block Making Machines adopt international most advanced Moulding Way that is Hydraulic Pressure with Vibration.The Block Quality is higher than blocks made by simple vibration and gravity molded.Take Chinese Standard Solid Bricks 240115x53mm for example, the brick strength can be reached 15Mpa, for Hollow Block 390190x190mm can reach 7.5Mpa and pavers 200100x60mm can reach 50Mpa,what is more,we can changed it according to your needs..The Quality Requirements of all the countries can be reached.