Introduction

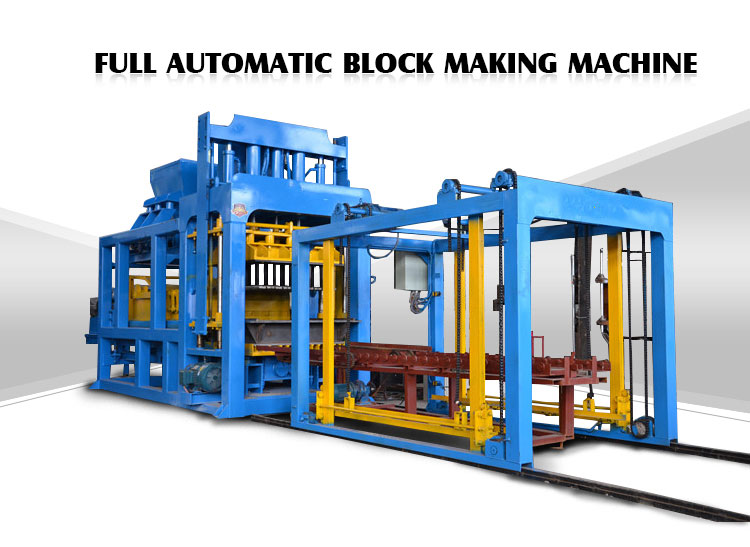

1. Super-strong steel structure made of extensive imported original parts, ensuring more stability and reliability for the concrete block machine body.

2. The whole process uses a PLC aptitude control and dialogue system of human-machine interface, easy to analyze the chance signal, ensure the best operation effect.

3. High-efficient and super-strong vibration system, computer-control flow pressure of the hydraulic system, realize vertically synchronous vibration, frequency conversion, and braking, with synthetic output compounded with double vibration sources, thus greatly increase product compactness and mould-box service life.

4. The cloth system adopts semi-closed screen reticular rotational feeding unit to feed materials forcedly, with evenness and even speed, ensuring product intensity.

5. Fitted with special hydraulic loading unit, readily realize mass and automatic production, saving a great deal of human power, maintenance field, and circulating fund investment.

|

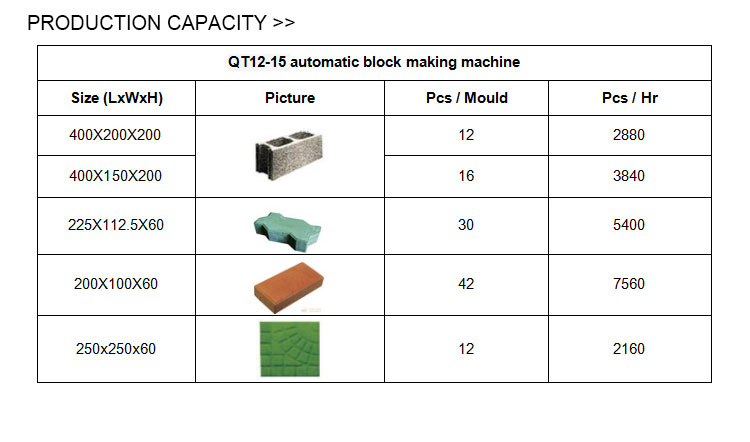

Technical Parameters of QT12-15 automatic brick making machine |

|

|

Overall Dimension |

9350*2520*2950mm |

|

vibration frequency |

60HZ |

|

Main Vibration Form |

Platform Vibration |

|

moulding mode |

load automatically,vibration moulding |

|

Pallet Size |

1300*900mm |

|

Molding cycle |

15-20s |

|

Overall Power |

44W |

|

Vibration Force |

100KN |

|

Total Mass |

12T |

|

Demolding method |

Hydraulic |

|

General water consumption |

12T/Day |

|

Factory Area |

1200m2 |

|

Applied Products |

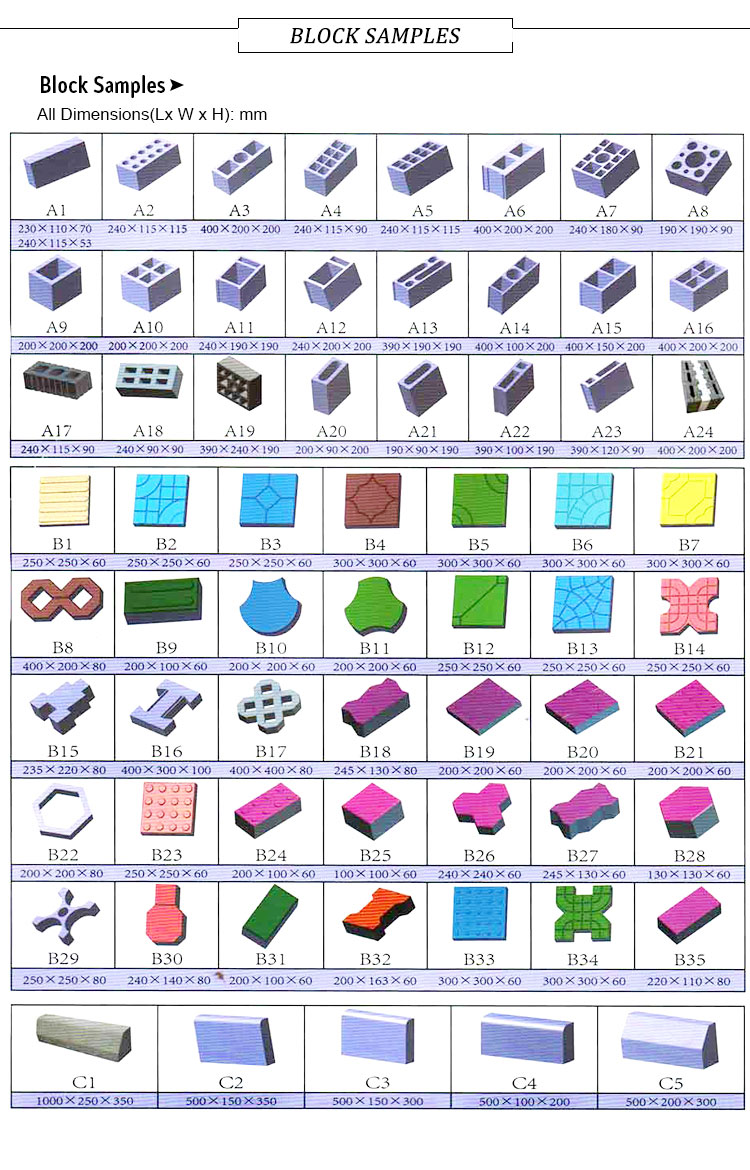

Concrete blocks, hollow/solid blocks, pavers, interlocking blocks , curbstone, colored pavers ,etc. |

|

Raw Material |

Crushed stone, sand , cement, dust, and fly ash, gravel, slag, and other raw |