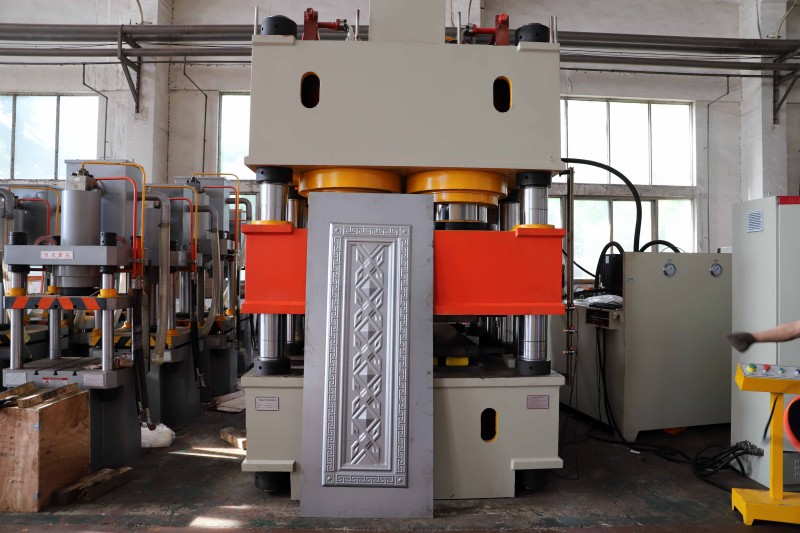

steel panel embossing machine

-steel embossing series

-door skin press machine

Hydraulic press mainly applies to

Embossing forming of steel wood door Steel plate embossing, container truck side plate stretching, steel frame panel room wall plate embossing, folding metal sliding door component molding, all kinds of metal plate one-time embossing embossing process.

Using area

the various walks of industry

metal / non-metallic materials

utensils stretching with cold press forming.

kitchenware,kitchensink,basin,bowl,pot Fire extinguishers, gas tanks, lunch boxes, trays, heads, floor drains, bathtubs, and other

products suitable for cold extrusion and stretch molding.etc.making machine.

door skin embossing press machine series

2000ton Steel Door Hydraulic Press Machine

2500ton Steel Door Hydraulic Press Machine

3000ton Steel Door Hydraulic Press Machine

3600ton Steel Door Hydraulic Press Machine

5000ton Steel Door Hydraulic Press Machine

-steel door skin thickness range

-1.0 mm stainless steel / iron

-1.2 mm stainless steel / iron

-1.5 mm stainless steel / iron

-2.0 mm stainless steel / iron

-2.5 mm stainless steel / iron

Ultra quiet design concept

A good hydraulic press needs at least two basic characteristics at the same time: Stable and strong pressure output The noise is even and quiet

When the machine is running without load, the noise is disordered and abnormal noise appears, which proves that the quality of the machine is poor. When the Embossing machine 3600 ton steel door skin hydraulic press is in full load operation, the noise is chaotic, which often indicates that the machine mechanism design is unreasonable, the machining accuracy is not enough, or there are hidden troubles

More powerful-- structure design

Strengthen the tempering and aging treatment of cylinder block and column, further strengthen the rigidity of fuselage, ensure the accuracy of physical structure after processing, and ensure long-term work without deformation, low wear and low noise.

The welded structure of steel plate welding beam has kept zero damage for eight consecutive years, and the technical team has continuously optimized the machine design for five consecutive years to repeatedly strengthen the overall performance.

More longer-- using life of machine

The optimization and upgrading of each component determines the continuous stability of the overall structure. Just like the pyramid, the standardized processing of bottom accessories is a strong guarantee for shaping the perfect quality. We don't believe in brand patchwork, we always adhere to the optimal performance combination The continuous improvement of the strength of the processing design team is the core to improve the quality of our machines.

Lower-- maintenance hassle

Our company has been committed to the research and development of hydraulic press technology for a long time. Through 16 years of production experience, we continuously improve the detail quality, high-precision processing and high standard design of the machine, From the material selecion of a screw gasket to the verification of technical principles, The national senior researcher leads the technical team from theoretical production to customer use, to repeatedly verify and innovate. By improving the continuous and stable endurance of each part, Ensure that the running accuracy and structural stability of the machine will not be reduced rapidly due to natural wear, So as to achieve the machine has been very normal good use experience.

Keep you away from repeated maintenance, Stay away from the long after-sales waiting, Keep away from unexpected project losses due to machine failure

Contact factory directly