Product Introduction

1.Advanced techniques made the host machine designed reasonably and beautiful.

2.Equipped with box vibration, hydraulic stripping, automatically feeding system .So the block density becomes higher, shaping speed quicker and block strength more even.also the machine failure rate is low.

3.Multidirectional automatically moving saving labor power and raising the efficiency.It can produce more than 22000pcs blocks one day

4.High quality of steel and precision welding made the machine a longer service life .

5.Hydraulic system made less fault during work.

6.No need pallent, so it will saved much money and avoide the blocks suffering second demage.

7.It has so much function features, such as low price, reliable performance, easy operated, stable , lower power consumption. Mass raw material can be used during production, for concrete, cement, small stone , powder ,san ,coal gangue, slag , construction waste and so on.

Technical Parameters of QMY12-15 block machine

|

Overall dimension |

3150*1800*2400mm |

|

Demold method |

Hydraulic |

|

Turning method |

Hydraulic |

|

Hydraulic system pressure |

16-20Mpa |

|

Excitation frequency |

3200Hz |

|

Total power |

16KW |

|

Total mass |

4200KG |

|

Molding cycle |

10-15S |

|

Molding |

12Pcs/mold(400*200*200 mm) |

|

Moving method |

Automatically move and hydraulic steering |

|

Vibration mode |

Three-dimensional mold vibration |

|

Raw material |

Crushed stone, sand, cement, dust and coal fly ash, cinder, slag, gangue, gravel, perlite, and other industrial wastes. |

Product Detail

Supporting Facility

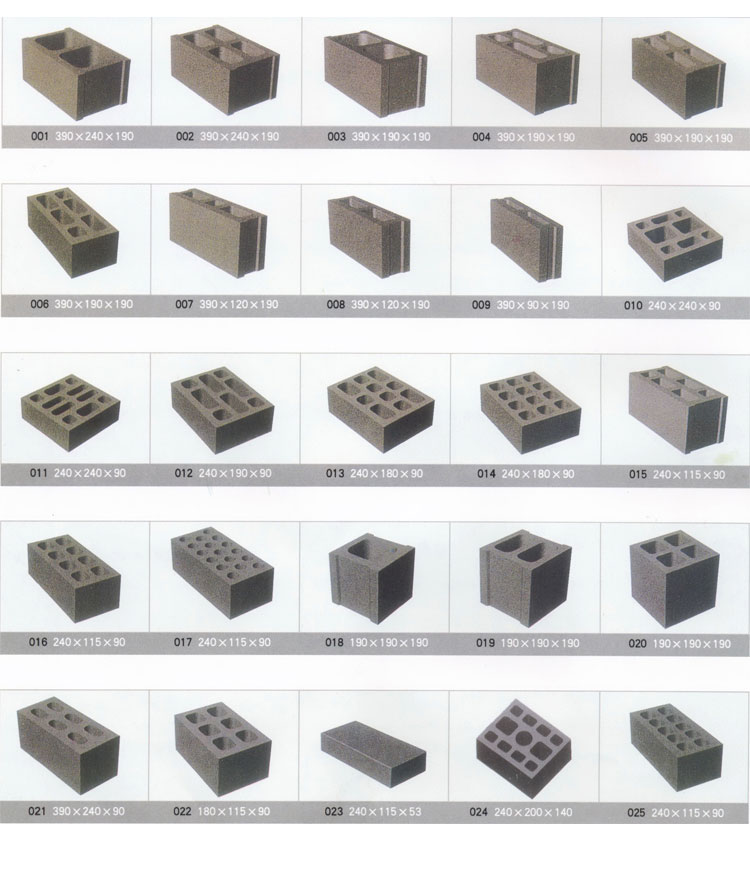

Block Samples