QT6-15 uganda automatic concrete cement interlocking paver hollow block making machine price

Qt6-15 hydraulic concrete brick making machine adopts imported color touch screen and PLC to control and equipped with data input and output device. It is a medium type of modern cement brick making machine with high efficiency and energy saving, large output, good quality and small investment. It is the first choice of hydraulic brick making machine for small and medium-sized brick factories. As long as the replacement of mold can produce highway shoulder, river brick, slope brick, square brick, dock brick, grass planting brick and other products.

1.Main Technical Specifications

| Dimension of host machine | 4400×2000×2750mm |

| Pallet size | 900 ×700 ×30mm |

| Weight of host machine | 7.9T |

| Vibration force | 50-70KN |

| Installed capacity | 45kw |

| Molding cycle | 15-20s |

| Intensity of pressure | 15-20mpa |

| Vibration frequency | 2800-4500 |

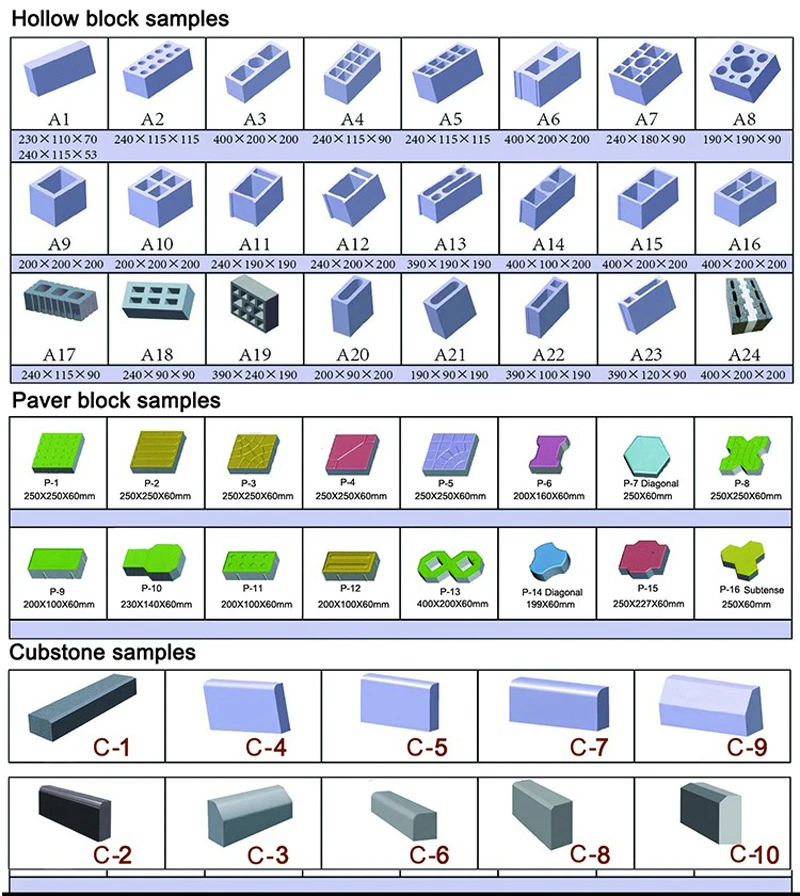

2.Theoretical capacity

|

Block type |

Picture |

Size (L*W*H) |

Pcs/mould |

Pcs/day |

|

Hollow block |

|

400×200×200mm |

6 |

11520 |

|

Hollow block |

|

400×150×200mm |

7 |

13440 |

|

Hourdi block |

|

530×160×195mm |

7 |

13440 |

|

Stock block |

|

220×110×75mm |

24 |

46080 |

|

Paving block |

|

200×100×60mm |

27 |

38880 |

|

Interlocking brick |

|

225×112.5×60mm |

15 |

21600 |

Other details about the hollow block machine you may interested

1).Supply ability of our factory: 50 sets per momth

2).Machine color: according to your requirement

3).Block mould: One set free for you,others according different size different price.

4).Generator needed: 100kw.

5).Working area needed: about 3000-4000m2.

6).Delivery port: Qingdao,China.

7).Delivery date:1 set,about need 15-20 days;more than 1 set,need to be negotiate.

8).Payment: You can choose the payment convenience by your side.

9).We are concrete hollow block making machine factory directly, not trading company, and we can arrange engineer to your side install the machine and training workers at the first time,you no need worry about the after sale service.

|

QT5-15 Automatic Block Production Line |

|||

|

No. |

Name |

Quantity |

Note |

|

1 |

PLD1200 Batching Machine |

1 Set |

Include Sieve System |

|

2 |

JS500 Mixer |

1 Set |

|

|

3 |

Belt Conveyor |

1 Set |

|

|

4 |

Concrete Feeder |

1 Set |

Include Pallet Conveyor |

|

5 |

Main Machine |

1 Set |

Include One Mould |

|

6 |

Wet Block Conveyor |

1 Set |

|

|

7 |

Automatic Stacker |

1 Set |

|

|

8 |

Hydraulic Oil Station |

1 Set |

|

|

9 |

Electric Control Cabinet |

1 Set |

|

|

10 |

Color Feeder |

1 Set |

Optional Part |

|

11 |

Pallet |

1500 Pcs |

Optional Part |

1. The whole concrete interlocking block making machine production line equipment is mainly the full container sea shipping,

2. Block making machine for sale equipment finish manufacturing and testing, next to clean up, and then do another paint protection,

3. Before shipment to use plastic film winding, wrapped the entire cement brick machine in case of water or moisture,

4. Then load brick machines into the container by forklift.

5. During loading to tighten the machine with reinforcement ring in container, so as to avoid the damage by transport bumps on the hollow block making machine.