Product Picture

Product Parameters

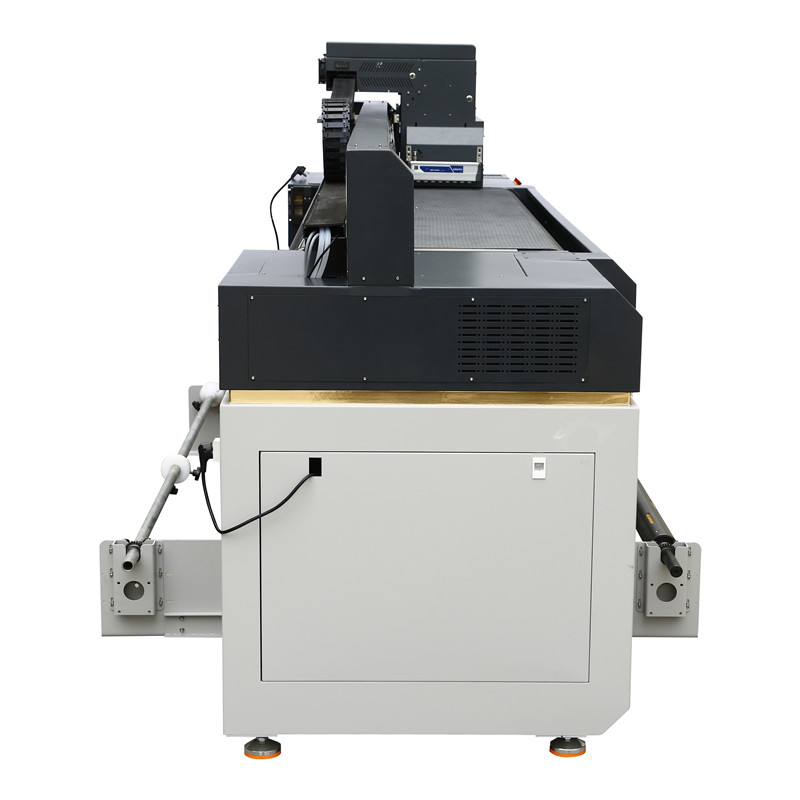

Product Name: D2000 Hybrid Flatbed&roll to roll printer

| Print Technology | ||

| Print Format | 180 cm | |

| Print Height | 8.5 cm | |

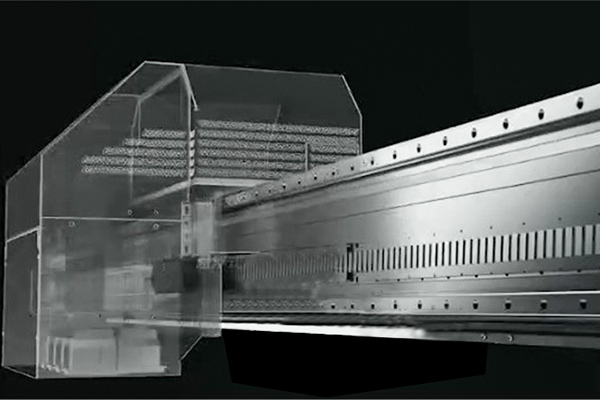

| Head Model | 2-8 PCS RICOH G5 | |

| Color Set | CMYK+W+V | |

| Control System | UMC | |

| RIP Software | Printfactory | |

| Print Direction | Uni/ Bi-directional, Front/ Rear Alternative | |

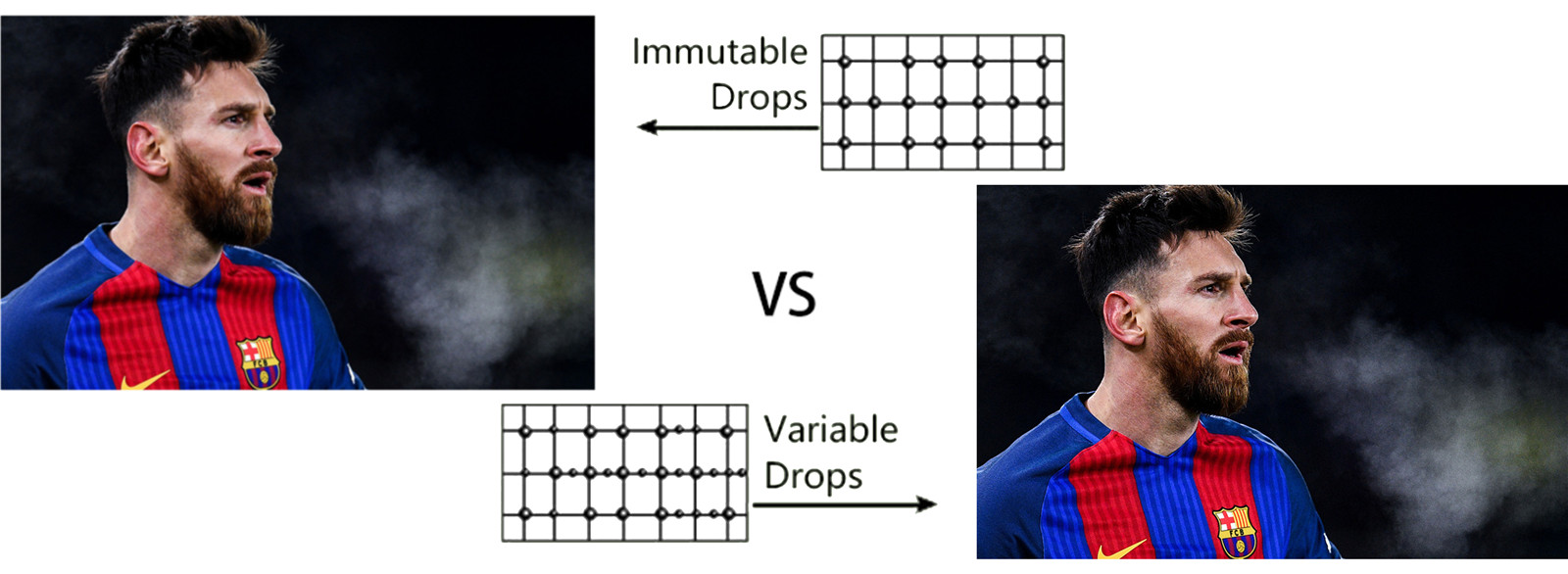

| Resolution |

4 PASS : 720 x 600 dpi 6 PASS : 720 x 900 dpi 8 PASS : 720 x 1200dpi |

|

| Print Speed |

Production mode: 34-17 sq.m/h Quality mode: 25.7-12.83 sq.m/h High resolution mode:17- 8.5 sq.m/h |

|

| Machine Highlight | ||

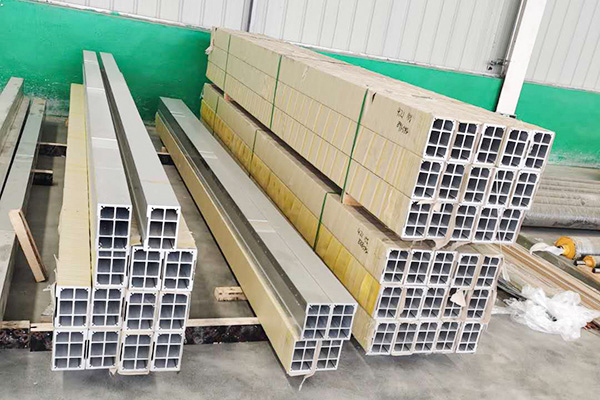

| Heavy Duty frame | Strengthened Aluminum beam & metal base | |

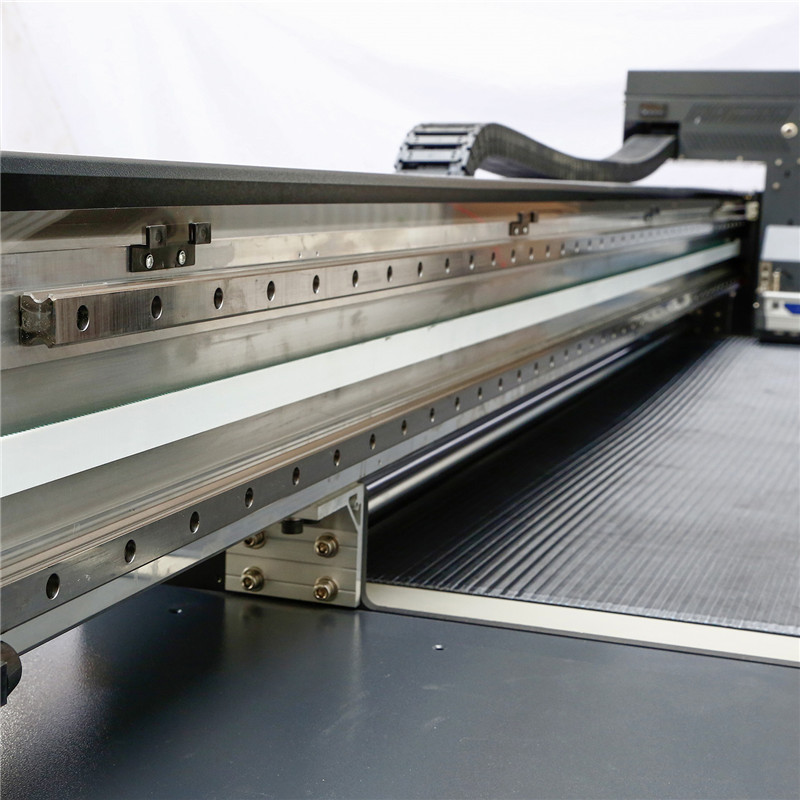

| Driving Mode | HIWIN linear rail + Leadshine Servo motor + import Drag chain | |

| Feeding & taking up Mode | roll to roll roller and Conveyor belt | |

| Work Table | Anodized aluminum Table +Vaccum Motor | |

| Ink System | Negative pressure Ink supply + White Ink stirring and circulation + Ink-lack Warning | |

| Curing System | imported LED lamp, 30000 hours lifespan, Water cooling Chiller | |

| Head Cleaning | Automatic by Program / Positive Pressure Clean | |

| Height Detection | Semi-Automatic sensor | |

| Others | ||

| PC Configuration | Win7/ Win10, 64 bit, CPU≥ i5, RAM ≥8GB, Space for Disk C≥100G | |

| Signal Transmission | USB 2.0 | |

| Color Control | Comply with ICC standards, with curve and density adjustment function | |

| File Format | TIFF/ JPEG/ POSTscript3/ PDF | |

| Power Supply | AC220V,50/ 60HZ | |

| Noise | Standby < 32 dB ; Working < 65 dB | |

| Machine Size | 3.3 m x 1.5 m x 1.57 m | |

| Packing Size | 3.5 m x 1.7 m x 1.8 m | |

| Net Weight | 840 KG | |

| Gross Weight | 1000 KG | |

Product Details

OEM Available Always For You based On Our Rich Experience In Uv Printer Since 2005’S.OEM Available Always For You based On Our Rich Experience In Uv Printer Since 2005’S.

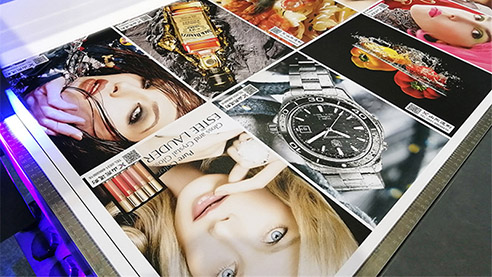

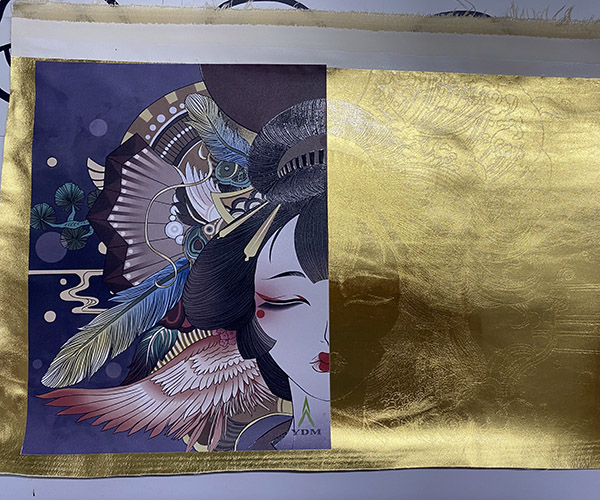

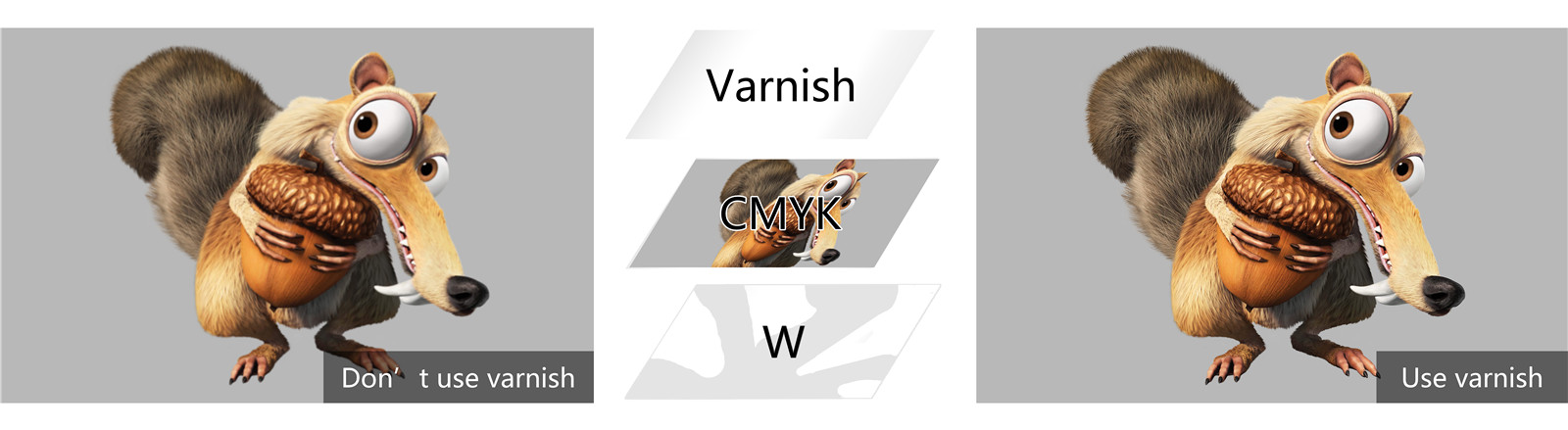

CMYK W V can be printed at the one time,UV varnish is cured by passing it under an ultraviolet light which quickly dries and hardens the varnish, creating a super high gloss varnish and offers the highest protection between varnish, aqueous and UV. Varnishing a product with UV will make it look much more professional, as well as making it much more attractive.Varnishing increases the perceived quality of the product. In addition, it is an economical and user-friendly process that can be easily applied by adding spot finishes or additional processes to the entire sheet. It can be manipulated to achieve the desired result

Productive Process

Machine Assembly&Testing

Application

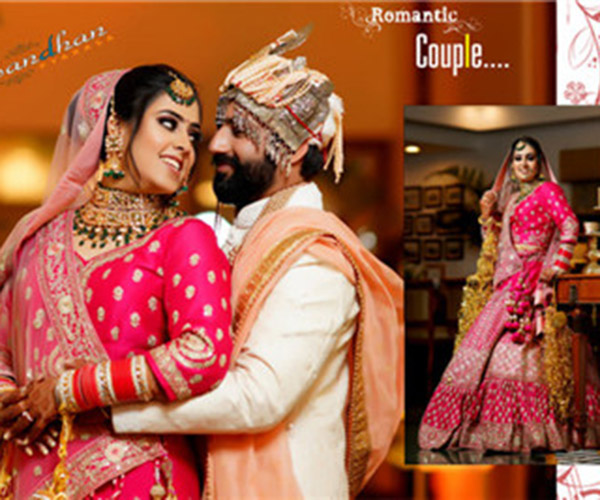

UV printer is used mainly for printing on things like customized products and other flat surface objects. UV has a wide range of substrates that can be printed on like glass, metal, wood, plastics, ceramics and many more,Let us see some printed samples by YDM UV Printer